Register to continue with the purchase.Register to download the Installation Guide.

Kbike

Special parts and accessories for Ducati

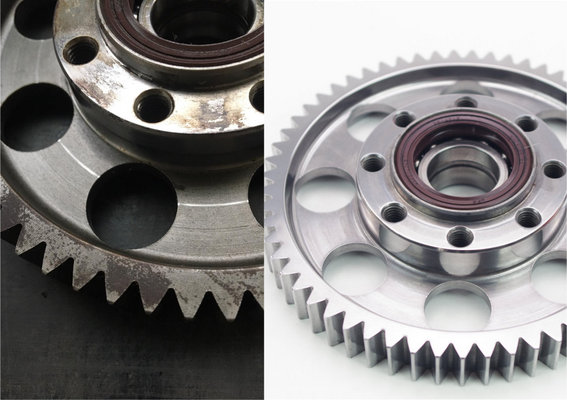

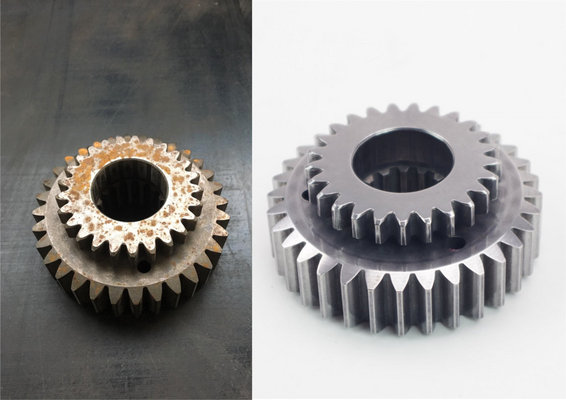

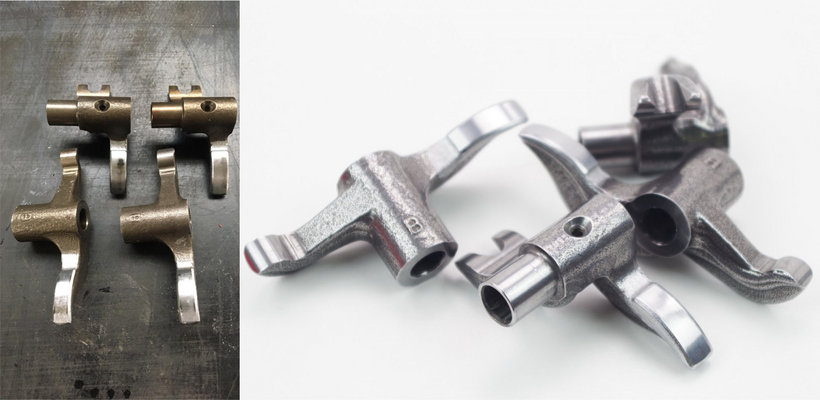

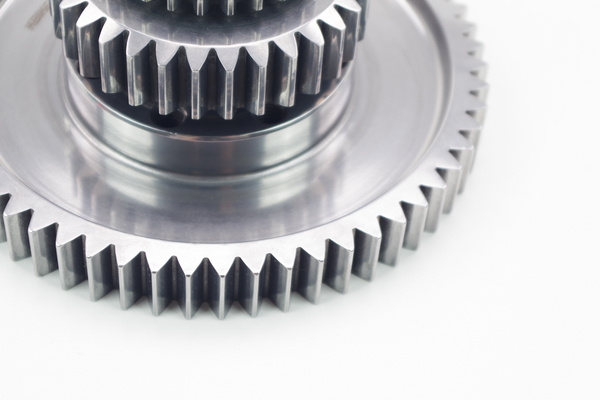

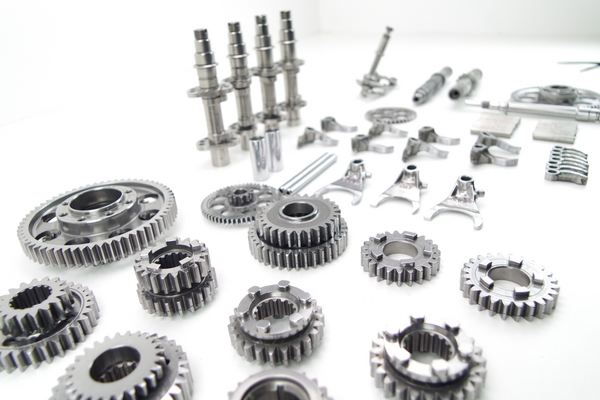

Two parts that rub each other in an engine of a motorcycle, for example the camshafts, gear wheels, shift shafts and various other gears produce friction and heat due to the roughness of the surfaces.

With the ISF process a surface with a very low roughness is generated, in fact the isotropic surface allows to obtain surfaces with roughness lower than 10 thousandths of micron (nanometers) and a non-oriented surface texture.

Conventional vibrating equipment is used in combination with non-abrasive solutions and accelerating refining chemicals that are safe and environmentally friendly.

The process is complex and is carried out in aqueous solution and therefore the pieces they do not undergo alterations due to overheating, preserving the tolerances.

An ISF surface reduces friction and wear, increases the life of parts and improves their corrosion resistance. The process is mainly used in motorsport, which is why we offer it to our customers.

We perform this treatment directly in Kbike workshops with our own machinery and we use the same technique used on components for competitive use worldwide, so we are able to offer the highest quality and potential from the piece that is given to us.

What can you expect after the ISF?

Reduced contact fatigue

Increased power density

Lower lubrication requirements and costs

Lower operating temperatures

Reduced vibrations and noises

Wear of the parts much lower

Greater output power

Reduced fuel consumption

No pitting on the gears

Longevity of the parts

Less maintenance costs

No shrinking of the gears

Better aesthetics

With the ISF process a surface with a very low roughness is generated, in fact the isotropic surface allows to obtain surfaces with roughness lower than 10 thousandths of micron (nanometers) and a non-oriented surface texture.

Conventional vibrating equipment is used in combination with non-abrasive solutions and accelerating refining chemicals that are safe and environmentally friendly.

The process is complex and is carried out in aqueous solution and therefore the pieces they do not undergo alterations due to overheating, preserving the tolerances.

An ISF surface reduces friction and wear, increases the life of parts and improves their corrosion resistance. The process is mainly used in motorsport, which is why we offer it to our customers.

We perform this treatment directly in Kbike workshops with our own machinery and we use the same technique used on components for competitive use worldwide, so we are able to offer the highest quality and potential from the piece that is given to us.

What can you expect after the ISF?

Reduced contact fatigue

Increased power density

Lower lubrication requirements and costs

Lower operating temperatures

Reduced vibrations and noises

Wear of the parts much lower

Greater output power

Reduced fuel consumption

No pitting on the gears

Longevity of the parts

Less maintenance costs

No shrinking of the gears

Better aesthetics

In order to perform this treatment with the engine parts, please send us an email to this address info@kbike.it sending us the images the exact number and weight of the parts you send us, in this way we will be able to inform you in advance on costs.

We ship worldwide

We ship worldwide